GRADING

NATUR

- Variety of colours and natural discolouration, natural grain of wood;

- Sound and pin knots up to 15mm;

- Filled knots up to 10mm;

- Group knots up to 8mm;

- Sapwood not allowed;

- Silver grains allowed;

CHARACTER

- Discolouration no restrictions, natural grain of wood;

- Sound and pin knots unlimited;

- Filled knots up to 50 mm,

- Group knots allowed unlimited;

- Outside sapwood 30 % lengh allowed;

- Silver grains allowed;

- Filled cracks allowed;

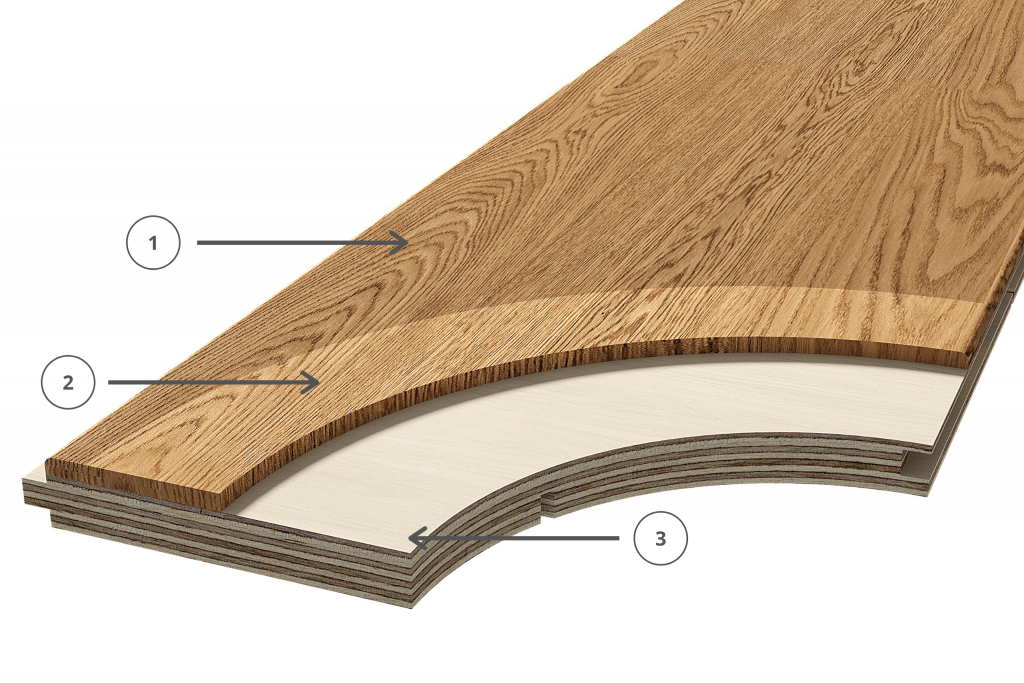

STRUCTURE

1 — Protective finish. 5 layers of UV hardened lacquer or 3 layers of UV hardened oil

2 — Top layer. 3 mm Oak

3 — Backing layer. 10 mm water resistant birch plywood

LAYOUT

At Grigio, we feel responsible for each flooring we produce and renovate, and want to ensure it maintains its quality and longevity even after long years of usage. Therefore, we apply a special protective coating on all our floors, preserving their functionality and aesthetics and making their maintenance as easy as never before.

3 layers of UV hardened oil

Instead of lacquer, your floors can also be covered with three layers of a special protective UV-cured oil coating. Oiled floors absorb liquid spills quicker than lacquered ones and are less resistant to dirt, so it is important to clean them as soon as possible. However, if they do get damaged or dirty, repairing them is much easier. One of the main factors which cause wooden floors to lose their colour and age is sunlight and UV rays. Our special UV oil coating slows down this process and preserves your floor’s durability.Follow these tips to make sure you take the best possible care of your oiled floors:

- Remove any dirt, sand or gravel as soon as possible to avoid scratching

- Only use special cleaning and maintenance products for oiled floors. Using unsuitable products may lead to both functional and aesthetic damage, such as stains, discoloration, changes in the slipperiness or gloss of the floor

- To remove dust, use a soft dry or slightly damp cloth or a vacuum cleaner or with a special nozzle for wooden floors. Make sure not leave any wet stains / water marks

- To prevent dirt from outside getting on your floor, place a doormat or a rug at every exit of the room

- Attach felt pads to the legs of the furniture

- In case of using a wheelchair, place a protective mat under it

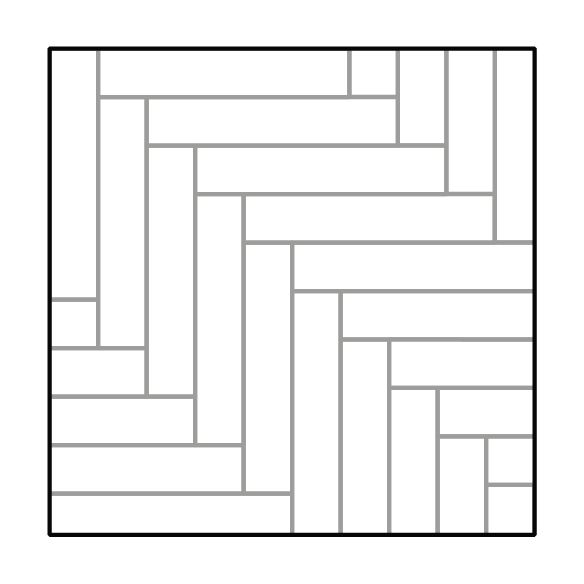

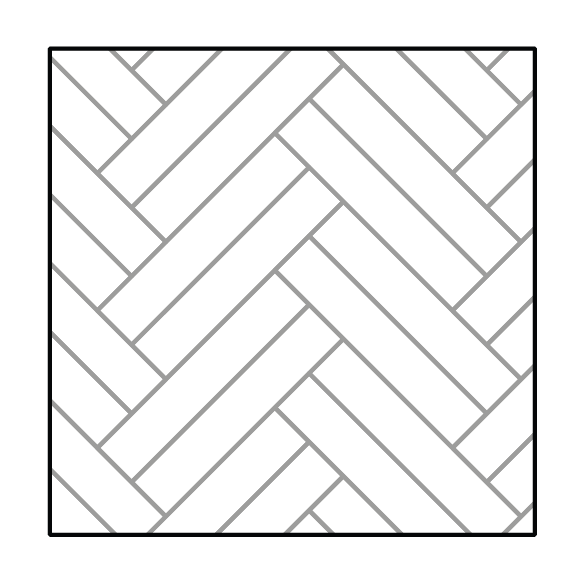

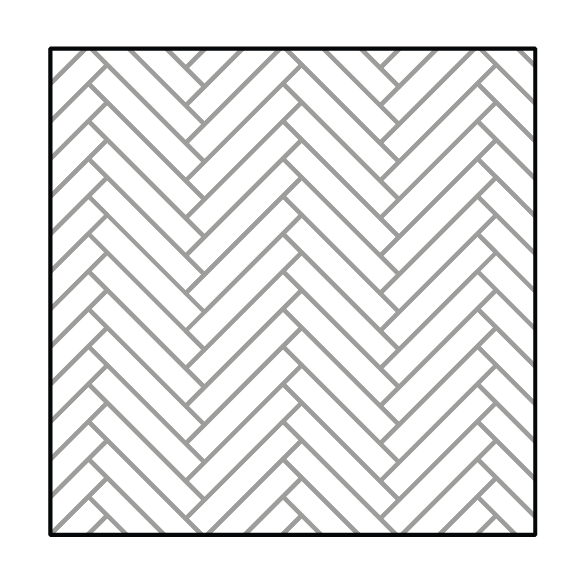

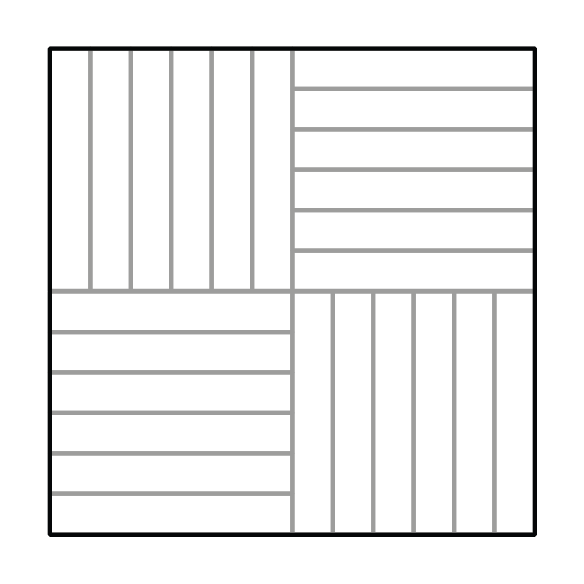

PATTERNS AVAILABLE ON OUR FLOOR

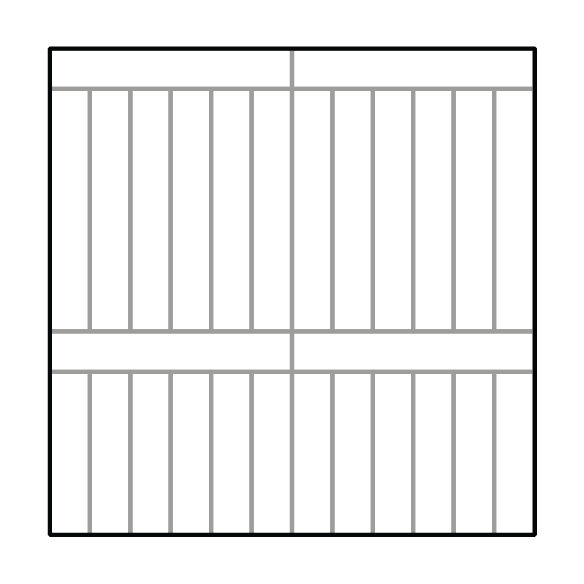

Plank

Diagonal plank

Herringbone

Diagonal herringbone

Double herringbone

Small herringbone

Square basket

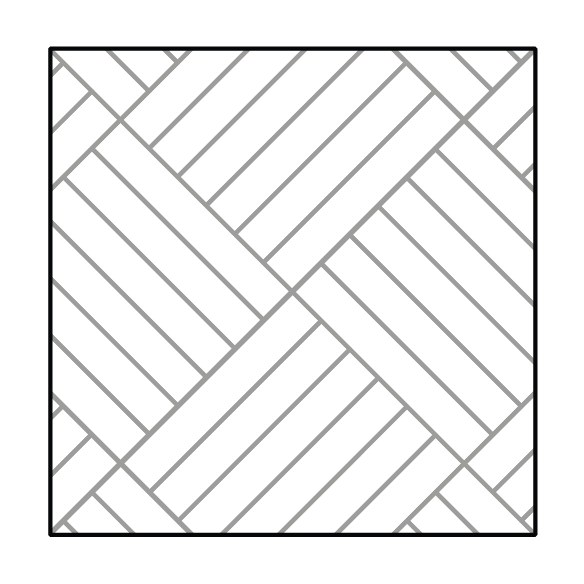

Diagonal basket

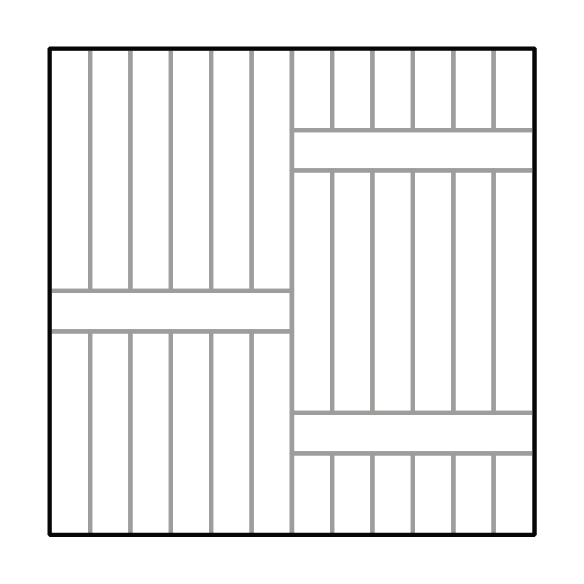

Blocker

Head and blocker

CERTIFICATES

At Grigio, we strive for excellence and quality.

Seeking to prove our responsibility both towards our customers and employees, we have carefully tested all of our products to ensure they meet the highest standards applicable in the modern-day wood production industry.

Our certifications include:

- FSC, guaranteeing all our products come entirely from FSC-certified, well-managed forests, preserving biodiversity and ensuring sustained economic viability

- CE, declaring our production complies with the essential requirements of the relevant European health, safety and environmental protection legislation.

- Flammability testing Certification, ensuring our products meet all necessary safety standards set in the wood production industry

- Slip Resistance testing Certification, guaranteeing our flooring is safe for occupants so they can avoid potentially dangerous slips and falls

- FEP (European Federation of Parquet Industry) Association membership Certification

The entirety of our production is guided by the principles set out in these certifications, so you can be sure you will get only the best-quality, safe and effective flooring products.